Casting CAE Analysis

In the design phase of casting molds, we use Pro Cast for casting CAE simulation analysis to analyze the possible locations of shrinkage and porosity risks inside the castings, improve the design of the molds, and reduce the risk of internal defects in the castings from the root during the design phase. Our casting engineers are fully involved in the development process of our casting suppliers, helping them complete casting process design and verification.

Castings Material Test

Do chemical compositions test & mechanical properties test with test bars which from same batch pouring and finish the reports for materials. The test bars after testing will be stored for 3 年.

3D scanning of castings

For castings with complex shapes, when the first batch of casting samples are completed, 3D scanning is performed to confirm whether the dimensions and shape of the castings match the 3D drawings of the castings.The application of 3D scanning technology has significantly improved the efficiency and accuracy of casting size and shape inspection.

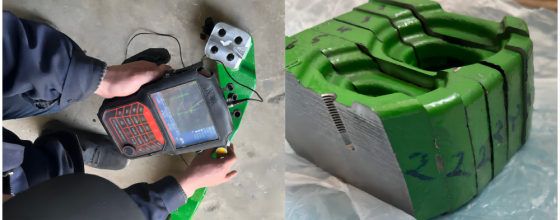

UT and Cutting inspection

For the first batch of casting samples, we will implement UT testing, and then cut one sample to observe and verify whether the internal defects of the casting meet the casting process design expectations.

Dimensions inspection by CMM

After the machining of the parts is completed, we will inspect the product dimensions according to the control plan. For key dimensions and geometric tolerances, we will use CMM for inspection.